Choosing a pressure controller

There are many different methods for pressure control.

Here we present a brief overview of these methods and discuss common use cases and applications for each.

Pressure reducing regulators

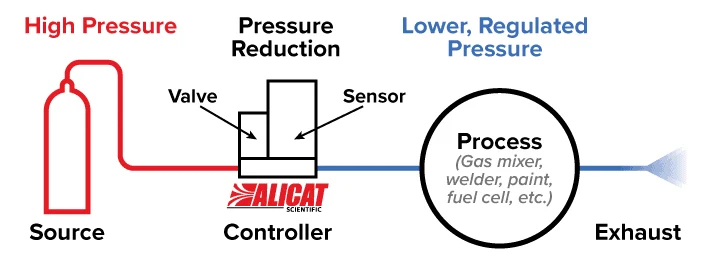

Pressure reducing regulators reduce a higher supply pressure at the inlet down to a regulated lower pressure at the outlet. These devices come in many shapes, sizes, and technologies. Any control valve is essentially a pressure reducing regulator, as opening or closing a valve inherently allows for greater or lower output pressures respectively. Some methods of pressure reducing regulators involve input and output pressure measurement so that manual or electronic setpoints for outputs can be set. Other methods simply create a more or less restricted output path. Common technologies include mechanical single and two stage regulators, needle valves, and single valve electronic pressure controllers.

Common applications include: gas mixing, welding, leak testing, automotive paint, and fuel cell testing

Figure 1. Using an Alicat pressure controller with upstream valve.

Back pressure regulators

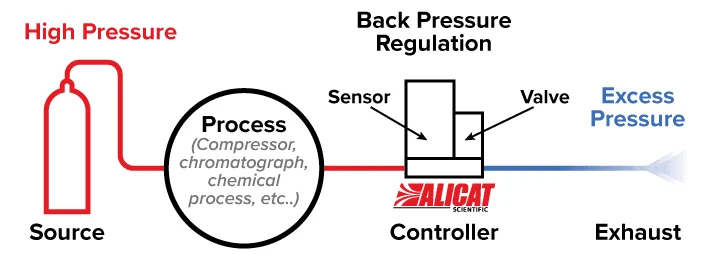

Back pressure regulators, on the other hand, control the restriction on the outlet of a system in order to control pressures that build or release upstream of the device. When gas pressure exceeds the intended setpoint, the back pressure regulator opens more to relieve the excess pressure. These devices similarly require a means of measuring upstream pressure, and reducing or increasing the restriction at the outlet of that system.

Common applications include: compressor testing and control, chromatography and analysis, chemical engineering, and pressure relief and safety

Figure 2. Using an Alicat pressure controller with downstream valve to control back pressure.

Back pressure control video demonstration

Closed volume pressure controllers

Both pressure reducing regulators and back pressure regulators are typically single valve systems, designed to control pressure in flowing systems. When working with closed or dead-ended volumes, it is common to use pressure controllers with either two proportional valves or a proportional valve on the inlet and a digital valve on the outlet. With these devices, the inlet valve allows pressure into the system while the exhaust valve relieves pressure. Many dome loaded pressure regulators utilized closed volume pressure controllers to control their internal mechanical setpoints.

Common applications include: fluid dispensing, micro-fluidic control, and sensor testing