Calibration and accuracy specifications for Alicat devices

Each device that goes through an Alicat calibration comes with a NIST-traceable Certificate of Calibration. This guarantees that the device’s calibration can be traced back to primary SI standards such as mass and pressure. As a result, an Alicat device will output mass flow rates that fall within the same accuracy range as measurements obtained by any other similar NIST-traceable unit with an identical accuracy specification.

When calibrating a device with a NIST-traceable transfer standard, each step of the process is carefully controlled to ensure reliable readings. Some factors that can lead to calibration errors include temperature and pressure variations, leaks, setpoint changes, and control instability. During the NIST-traceable calibration of an Alicat device, each of these variables is carefully monitored and controlled. This ensures your device is calibrated to output precise, high-accuracy mass flow readings.

How is my device calibrated?

Alicat calibrations evaluate readings at five points within the full scale range of your device: 0%, 25%, 50%, 75%, and 100% of full scale. You can also request a custom calibration, for which you choose the specific calibration points and may use more than 5. These readings are compared with readings taken from one of our in-house flow or pressure standards.

What does the calibration report tell me?

Every report contains three sections: device under test, equipment used, and calibration.

Device Under Test

This section contains information about your device and the conditions under which your device was calibrated.

- Range: The full scale range of the unit. For most devices, this will match the body size in the part number. Devices configured with custom ranges (those including the RANGE adder code) will be calibrated to the custom range.

- Process Gas: The pre-selected gas from the gas menu. This can be changed using the front panel, any communication protocol, or during recalibration.

- Calibration Gas: The gas used to calibrate the unit. Alicat calibrations use air unless a different calibration gas is specifically requested.

- Temperature: The temperature of the gas that was used to calibrate the device.

- Humidity: The ambient humidity of the Alicat facility at the time of calibration.

- Control Algorithm (P/D/I values): For controllers, the default tuning settings. Most devices will have only P and D settings.

- Calibration Procedure/Rev. #: The standard procedure and revision used to calibrate the device.

Device Under Test

Device Under Test

Equipment Used

This section gives information about the tools Alicat technicians used to calibrate your device.

- Type: The type of calibration performed.

- Tool Name: The tools used for the calibration.

- Manufacturer/Model: The manufacturer and model of the calibration tools, often including Alicat devices.

- Uncertainty: The uncertainty of the calibration tools.

- Due Date: The next date at which a NIST-traceable calibration should be performed on the tool.

Equipment Used

Calibration

This section contains information about the results of the calibration, with tools for interpreting these readings.

First, there is information about the conditions and parameters of the calibration.

- Accuracy: The uncertainty of the measurements (see below).

- Full Scale Range: The full scale range of the device being calibrated.

- Calibration Pressure: The pressure at which the calibration was performed.

- Valve Adjustment: For controllers, the inlet pressure (P1) and outlet pressure (P2) used to tune the valve.

Calibration

Valve Adjustment

Next, there is information on your device’s as-found and as-left data – its readings before and after calibration. This indicates whether the device was in-spec when it arrived for calibration, and if not, which points were out of tolerance. All devices returned for recalibration will have as-found data.

- Indicated: The reading from your Alicat device, in the same units as the full scale range (NLPM here).

- Actual: The reading from the device performing the calibration, in the same units as the full scale range (NLPM here).

- In Tolerance: Indicating whether the measured points were in or out of tolerance.

- Output: Your device’s analog outputs.

As-Found

As-Left

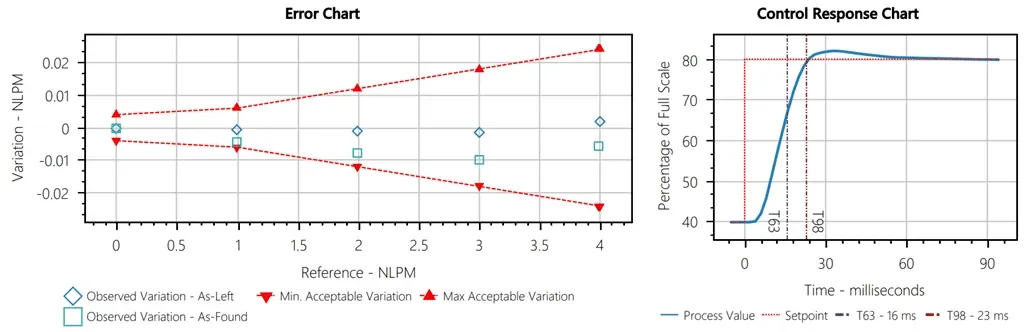

More recent calibration reports also include error and control response charts.

- Error Chart: As-found and as-left data with reference to tolerance values.

- Control Response Chart: For controllers, the valve response relative to a step change in setpoint, using the P1 and P2 specified in the Valve Adjustment table.

What does the accuracy specification tell me?

In the video, we look at the example of a 5 SLPM device with accuracy specification of ±0.8% of reading and ±0.2% of full scale. 0.8% of reading scales down with decreasing flow: when the meter is flowing at 100% of full scale, 0.8% of the reading is 40 SCCM, while 0.2% of full scale is 10 SCCM. The error at full scale is the total of these values, or ±50 SCCM.

But at 0.5% of full scale, 0.8% of the reading is 0.2 SCCM, while 0.2% of full scale is 10 SCCM. Again, the error is these values added together, or ±10.2 SCCM.

What calibration options are available?

- Bidirectional: For flow, gauge pressure, and differential pressure devices.

-

High Accuracy Calibration: Available for most mass flow and pressure devices. See the appropriate specification sheet for availability.

- FP-25: Alicat FP-25 devices receive NIST-traceable calibrations for mass flow, temperature, and barometric pressure. The flow calibration accuracy is 1% of reading.

- 3rd-Party 17025 Calibration Services: Alicat works with 3rd-party calibration houses to conduct 17025 calibrations. Following 17025 calibration, you will receive a standard Alicat NIST-traceable calibration documentation and a 17025 certificate of conformity provided by the 3rd-party. 17025 calibrations are available with L.A.B. or A2LA accreditation.

How do I recalibrate my device?

Annual recalibration is recommended for most Alicat devices. You can find the date of its most recent calibration on the back of the device, or stored in MENU > ABOUT > DEVICE INFO.

To schedule an Alicat recalibration service, complete the Service Request Form. On receipt of your request, Alicat will issue you an RMA (Return of Materials Authorization) and send you shipping instructions.