Flowing non-Newtonian fluids

Finding the right instrument to measure or control non-Newtonian fluids can be a challenge. Some popular flow technologies like electromagnetic meters can exhibit up to a 20% deviation in accuracy when used for such fluids. Ultrasonic flow meters have also shown up to 15% deviation when used for non-Newtonian fluids transitioning between laminar and turbulent flow. In this blog, we will discuss the challenges posed by non-Newtonian fluids and how Coriolis flow instruments have proven to be the most successful solution.

What are non-Newtonian fluids

Newtonian fluids—for example, water—exhibit a constant viscosity regardless of any applied force. Non-Newtonian fluids, on the other hand, change in viscosity depending on the type and magnitude of forces exerted upon them.

| Newtonian fluids | Non-Newtonian fluids |

| Water | Diesel exhaust fluid |

| Alcohol | Blood |

| Glycerol | Soap solutions |

| Gasoline | Honey |

The effect of shear stress

For any process fluid moving through a pipe, shear forces are caused by the molecules inside the fluid moving past each other. For Newtonian fluids, these shear forces do not lead to a change in viscosity, and the flows have predictable velocity profiles.

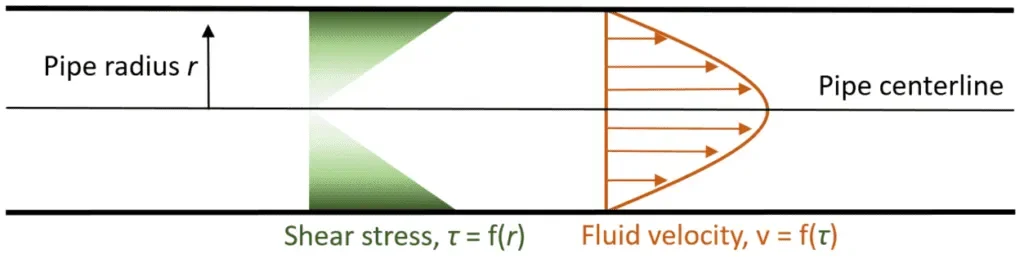

In the diagram below, you can see that when Newtonian fluids flow through a pipe, increased shear stress near the pipe walls causes a decrease in velocity. This leads to a faster fluid flow at the center of the pipe, and a slower fluid flow at the pipe walls. The resulting velocity profile is then predictable as a function of the shear stress.

Figure 1. Newtonian flow through a pipe

In contrast, the velocity profiles are not as predictable for non-Newtonian fluids, because the shear stress affects not only the velocity, but also the viscosity of the fluid. When the viscosity of the fluid changes as a function of this stress, the velocity profile through the pipe can be rendered asymmetrical, changing, and unpredictable.

How does shear stress affect viscosity for non-Newtonian fluids?

Non-Newtonian fluids can be classified into one of four groupings, characterized by the effect shear stresses have on their viscosities.

- Dilitant (shear thickening) fluid viscosity increases with shear stress

- Pseudoplastic (shear thinning) fluid viscosity decreases with shear stress

- Thixotropic fluid viscosity increases with shear stress over time

- Rheopectic fluid viscosity decreases with shear stress over time

Figure 2a. Effect of shear stress on non-Newtonian fluids (shear thickening & thinning)

Figure 2b. Effect of shear stress on non-Newtonian fluids (thixotropic & rheopectic)

What other conditions affect non-Newtonian fluids?

Process conditions can introduce further variability to a non-Newtonian fluid’s behavior. Changing parameters such as pipe diameter, flow rate, and pressure all have an effect on the magnitude of shear stress present, and thus also on the fluid’s viscosity and velocity profile.

Flowing non-Newtonian fluids using Coriolis technology

When selecting a flow meter or controller, it is critical to consider the behavior of fluids used in the process. Non-Newtonian fluids have different velocity profiles compared to Newtonian fluids, and also behave differently when transitioning between laminar and turbulent flows. These characteristics decrease the measurement accuracy of flow meters that rely on expected flow velocity profiles.

Coriolis mass flow instruments are able to accurately measure and control non-Newtonian fluid flow rates due to their unique operating principle which uses inertial forces to directly determine mass flow rates. This was validated by a University of Liverpool study that found Coriolis flow devices to operate within the specified accuracy tolerance when used with non-Newtonian fluids.

While Coriolis instruments have been shown to be the most effective solution for flowing non-Newtonian fluids, it is still important to be aware of the technology’s limitations. Some non-Newtonian fluids are highly viscous—for example, cement slurries, yogurt, and honey—and may not be compatible with certain Coriolis devices.

Less viscous non-Newtonian fluids, such as polymer solutions, are perfect for use with Coriolis instruments like Alicat’s CODA-Series mass flow meters and controllers. Diesel exhaust fluid (DEF) is a non-Newtonian fluid solution mixture of 32.5% urea and 67.5% DI water. This liquid is poured into many diesel truck engines to reduce emissions by breaking down soot and unburnt fuel into nitrogen and water byproducts. Testing of DEF efficacy and usage often requires accurate measurement of flow over set time periods. The accuracy of standard flow measurement technologies is hindered by the non-Newtonian fluid properties.