High flow control for gasification

Gasification is a process in which biomass or fossil fuel is converted into carbon monoxide, hydrogen, and carbon dioxide (syngas or synthetic gas).1 According to Carnot’s theorem of thermodynamic efficiency, the syngas produced is more energy-rich than organic fuel in its combustion due to higher combustion temperatures. Furthermore, syngas can be used directly in gas engines, kilns, boilers, and thermal oxidizers. In some parts of the world, syngas made from biomass is thought to be less expensive than fossil fuel and can be directly substituted in most applications. Furthermore, the quality of the syngas produced depends on the composition of the reaction, which ultimately relies on precise control of oxygen or air entering the gasification chamber.

Syngas can be created from a feedstock of biomass, municipal solid waste, medical waste, and even hazardous waste. While the amount of pollution created depends upon the feedstock, syngas burns cleaner than fossil fuels and has much lower emissions than greenhouse gases.

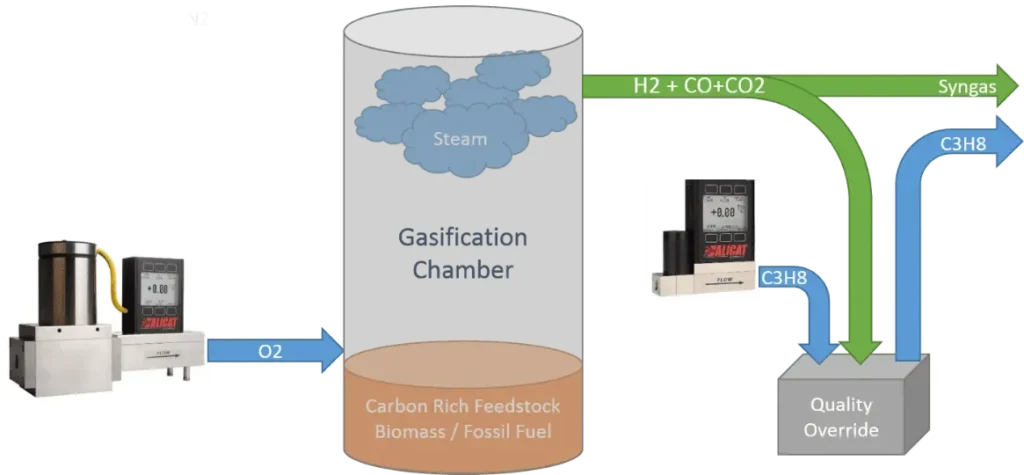

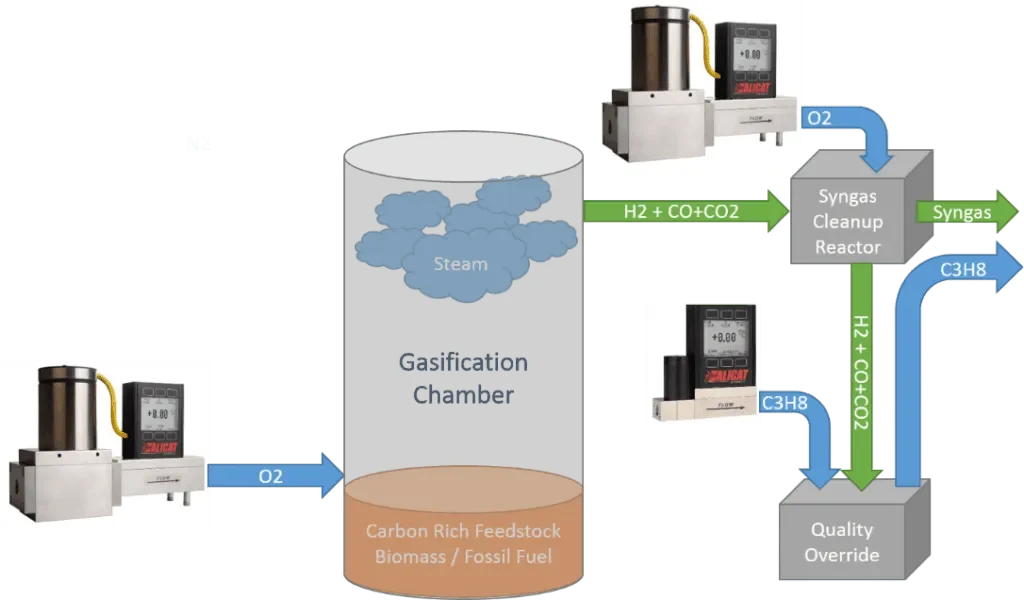

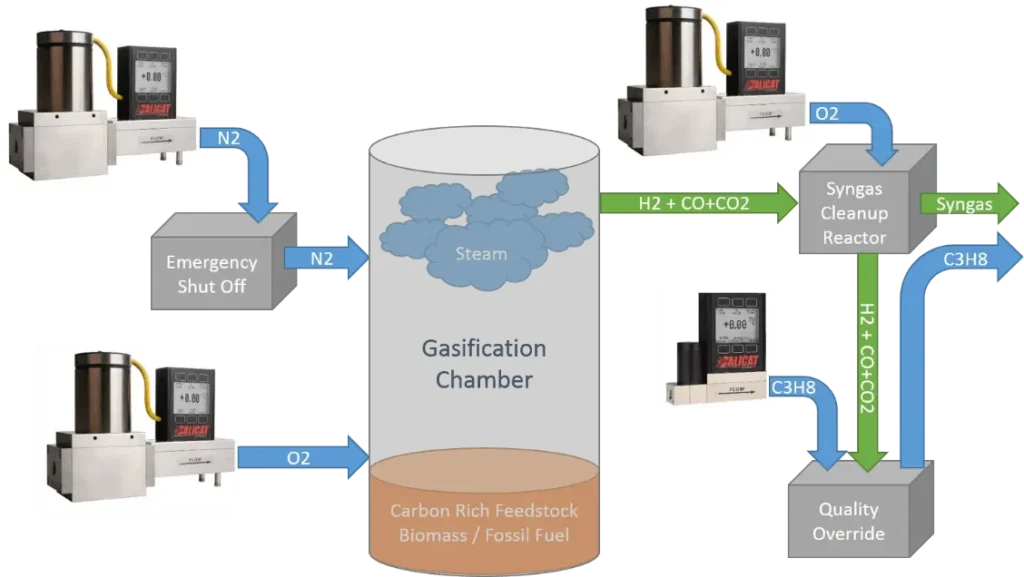

Creating syngas

Syngas is typically created from three major components: carbon, oxygen, and steam. The carbon and steam are created by heating the fuel, and the oxygen is added exogenously. The oxygen introduced will interact with the steam and carbon to ultimately create a mixture of hydrogen, carbon monoxide, and carbon dioxide. The particular composition of the syngas is dependent primarily on the amount of oxygen added to the system. Adding too much oxygen will result in a higher concentration of carbon dioxide and a correspondingly lower concentration of carbon monoxide. Such a mixture lowers the overall quality of the syngas and limits its applications. Alicat mass flow instrumentation can streamline and provide additional efficiency and safety in gasification and syngas product processes.

Due to the large size of most gasification chambers, a large flow rate is typically required. A large mass flow controller is a precise way to combine the high flow rates needed with the accuracy required to create syngas with an ideal composition. Alicat’s MCR-Series controllers use near-frictionless Rolamite proportional control valves to rapidly and precisely control flow rates up to 5000 SLPM. With an accuracy of ±(0.8% of reading + 0.2% of full scale range) extending to these high flow rates, precise composition can be ensured.

Improving poor batches

While the flow rate of oxygen can be precisely controlled, sometimes the concentration of syngas components is not as expected due to unforeseen variations in the feedstock or experimental setup. To combat this issue a simple quality control check can be inserted. When the quality of the syngas is less than ideal, usually by creating a larger percentage of CO2 than is desirable, a mass flow controller can be used to add propane to the mixture, rather than requiring a lengthy full system restart. This new mixture will more closely match the chemical properties of the desired composition and can be used in most applications. This compensation can be done easily via serial communication with the controller and integrated into an existing quality check program.

Additional refinements

After the syngas has been created, a cleanup reactor may be used to remove undesirable tar particulates. Particulates are often removed using cyclonic separation. In a cyclone separator with secondary input, oxygen is sprayed through nozzles to create a vortex. The particulates will be unable to follow the tight curve of the vortex due to the increased inertia caused by their larger density.2 A high-accuracy mass flow controller can ensure that particulates of the right density are separated efficiently by tightly controlling the oxygen flow. The syngas can be further cleaned with oil or water scrubbing to remove residual tar.

Safety first!

When working at such high temperatures with potentially combustible materials, purging the system quickly is sometimes necessary. A safety shut-off system can easily be configured with a mass flow controller to flood the chamber with nitrogen. These controllers can be built with a CSA Class 1, Division 2 (ATEX zone 2) area classification to ensure that local fire safety regulations are being met and the mass flow controller is suitable for the operating environment.

Conclusion

Syngas produced by this method can be used for hydrogen fuel cells, power generation, transportation fuels, and more. A common secondary product from this process is “biochar”. Biochar properties can be successfully predicted utilizing the van-Krevelen diagram.3 Biochar typically has hygroscopic properties and is highly useful in soil amendment, due to its inherent water retention, porous nature, and utility as a carbon source. When operating at higher temperatures, gasification will produce liquid stone and metal instead of biochar. These resulting products can be used as construction materials or high-density filler and have been proven to be non-leaching.4

Alicat mass flow controllers can be used in multiple areas of the gasification process: combustion, cleanup reactors, safety, and quality control. The precision and versatility of these units allow for more precise syngas production, redundancy between units, and extremely fast control. After all, the quality of the syngas produced is dependent upon the accurate and repeatable flow of oxygen into the gasification chamber.

References

1) Beychok, M.R., Process and environmental technology for producing SNG and liquid fuels, U.S. EPA report EPA-660/2-75-011, May 1975

2) Brand, J.F. et. al., Conceptual use of vortex technologies for syngas purification and separation in UCG applications, Journal of the South African…., Oct 2018

3) Krevelen D., van (1950). “Graphical-statistical method for the study of structure and reaction processes of coal“. Fuel. 29: 269–284., 1950

4) “The liquid stone produced by sierra energy’s fastox gasifier proven to be non leaching.” Sierra Energy www.sierraenergy.com/news/posts/2014/august/the-liquid-stone-produced-by-sierra-energys-fastox-gasifier-proven-to-be-non-leaching/. Accessed 9 April 2019