Measurement/control range and turndown ratio FAQ

Most Alicat devices have a 0.01–100% measurable/controllable range. If you are looking at an older spec sheet, this may instead be listed as a 10,000:1 turndown ratio. Here, we discuss full scale control range, flow measurement range, and turndown ratio.

What do full scale control range, flow measurement range, and turndown ratio actually mean?

- Steady state control range: The flow range in which the accuracy and repeatability listed in the spec sheet are guaranteed to apply. This term applies to controllers, and is a function of the valve and sensor package.

- Flow measurement range: The flow range in which the accuracy and repeatability listed in the spec sheet are guaranteed to apply. This term applies to meters, and is a function of the sensor package.

- Turndown ratio: The maximum usable reading divided by the minimum usable reading.

Why do some spec sheets list a turndown ratio while others do not?

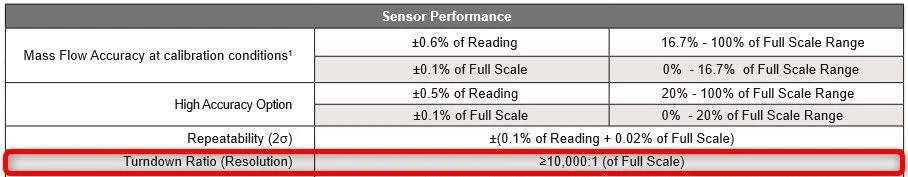

Older Alicat spec sheets included a “Turndown Ratio” (see Figure 1).

Figure 1. Outdated Alicat spec sheet for M–Series mass flow meters

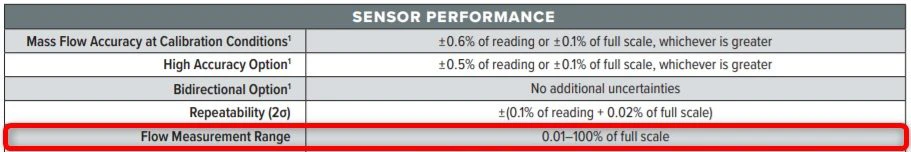

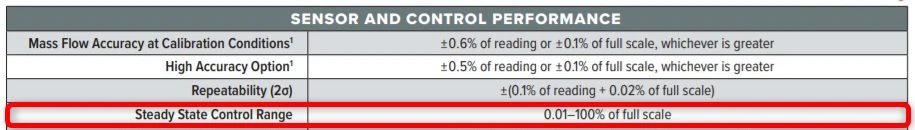

Newer spec sheets instead list “Flow Measurement Range” for meters (see Figure 2) or “Steady State Control Range” for controllers (see Figure 3).

Figure 2. Updated Alicat spec sheet for M–Series mass flow meters

Figure 3. Updated Alicat spec sheet for MC–Series mass flow controllers

If your spec sheet still lists a turndown ratio, it may be out of date, or may not have been updated yet.

How can the device have a measurement/control range of 0.01% of full scale (or a 10,000:1 turndown) and also an error of 10x the reading at the low end?

You may notice that at the bottom of the measurable/controllable range, the error in the accuracy reading is significantly larger than the reading itself.

If a device is operating within the “flow measurement range” or “steady state control range,” accuracy and repeatability of readings fall within the listed device specifications. Although the error is high at the low end, the device still supplies stable, repeatable readings that are useful to certain applications.

When am I able to take advantage of the entire measurement/control range?

It depends on your specific application requirements, accuracy needs, and overall control/measurement system.

The example below discusses an application that will be able to use the entire control/measurement range, and an application that will not be able to use the entire range.

Example:

An application requires you to control flows ranging from 3.05 SCCM to 8.90 SLPM. You are trying to determine if a single 10 SLPM controller is sufficient. When flowing at 8.90 SLPM, its accuracy is ± 0.0534 SLPM. When flowing at 3.05 SCCM, its accuracy is ± 10 SCCM.

- If you need accuracy at specific setpoints across the entire flow range, the error at the low end of the steady state control range will be too large for the 10 SLPM controller to be useful for low flow control in your application. You will therefore require multiple mass flow controllers to control the flow ranges you are using.

- If you need repeatable flows across a series of experiments, you can take advantage of the entire steady state control range and use a single 10 SLPM controller. This is often the case when controlling on a separate process parameter, and the large controllable range allows your setup to use fewer flow devices than would have otherwise been required.

Alicat applications engineers are available to help determine the best solution for your application. Contact us here.

Is “0.01–100% of full scale” referring to the 10,000:1 turndown ratio?

Yes. When older Alicat documentation uses the phrase “10,000:1 turndown ratio,” it is equivalent to the updated documentation stating “0.01–100% of full scale.”

Devices such as the MS-Series which operate at 1–100% of full scale may be described as having a 100:1 turndown ratio. Devices which operate at 0.5–100% of full scale may be described as having a 200:1 turndown ratio.

What is the accuracy of my device across the measurement/control range?

With a few exceptions, the measurement accuracy is not constant across your device’s entire flow range. For most Alicat devices, the accuracy of lower flows is determined by a percentage of the full scale flow of the device, and the accuracy of higher flows is determined by a percentage of the flow reading.

For some Alicat devices, such as the MS-Series, the accuracy across the entire device range is a percentage of the flow reading plus a percentage of the full scale flow.

Example:

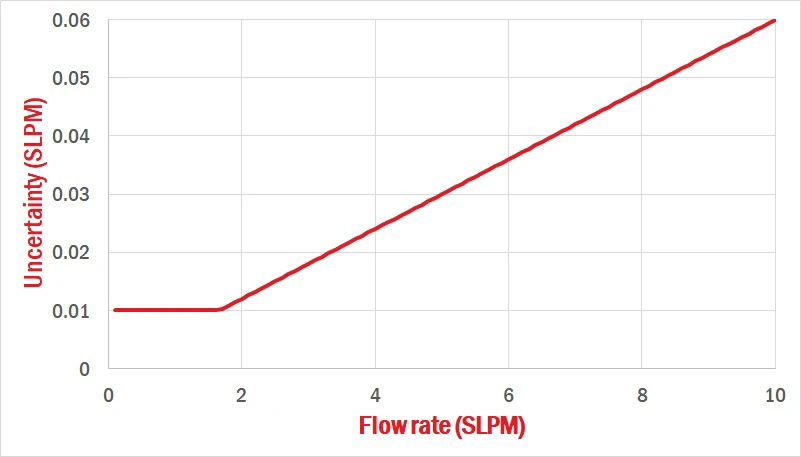

For a 10 SLPM MC–Series controller, the accuracy is either ± 0.6% of reading or ± 0.1% of full scale – whichever is greater.

This means that flow rates ranging from 1 SCCM to 1.67 SLPM will have an accuracy of ± 0.1% of full scale (.01 SLPM for the entire range). For flow rates from 1.67 SLPM to 10 SLPM, the accuracy will be ± 0.6% of reading (flow rate dependent).

Figure 4. Accuracy for MC controller over full steady state control range

What happens outside of the measurement/control range?

- Below the measurement/control range, the signal–to–noise ratio is too low to ensure resolved, repeatable readings.

- Above the measurement/control range, your device will provide readings up to 128% of the full scale range, although the accuracy and repeatability specs are not guaranteed above 100% of full scale.

Will different process conditions affect range, accuracy, or repeatability?

No. The range, accuracy, and repeatability all remain unchanged for both static and highly dynamic applications.