Thin Film Deposition

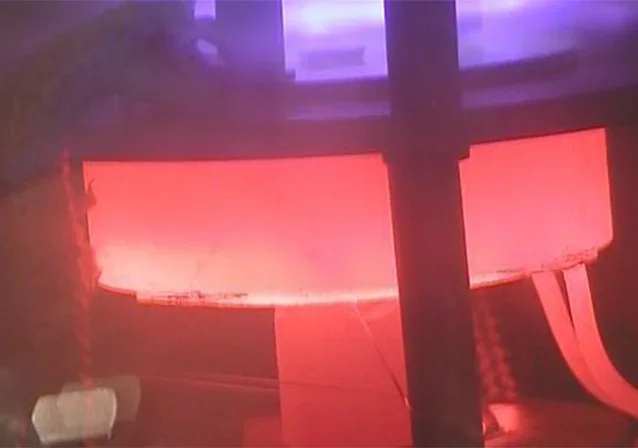

Producing uniform coatings requires fast, precise gas delivery into vacuum coating systems. This is critical in thin film applications from synthetic diamond production to photovoltaic coatings.

Optimize thin film deposition setups for maximum throughput and film quality

Alicat has a range of custom solutions specifically designed to upgrade existing vacuum setups.

- No warm-up time. Deposition cycles can begin immediately after turning on flow devices.

- Millisecond response time. Flow and pressure controllers immediately respond to process condition changes, maximizing uniformity and minimizing waste.

- Multi-gas compatibility. A single device can flow any of the gases needed in the deposition process, with high accuracy.

Upstream pressure control to increase stability and speed in deposition

Applications

Full-scale flow that doesn’t change with gases or process conditions

Alicat devices are pre-loaded with 98+ gas calibrations. Flow and pressure devices will maintain their stated flow ranges and accuracy specifications for any gas under standard process conditions.

316L stainless steel and FFKM elastomers ensure compatibility with corrosive gases and harsh elements.

You can switch gases in the field, with no downtime or recalibration required.

Designed to meet SEMI standards

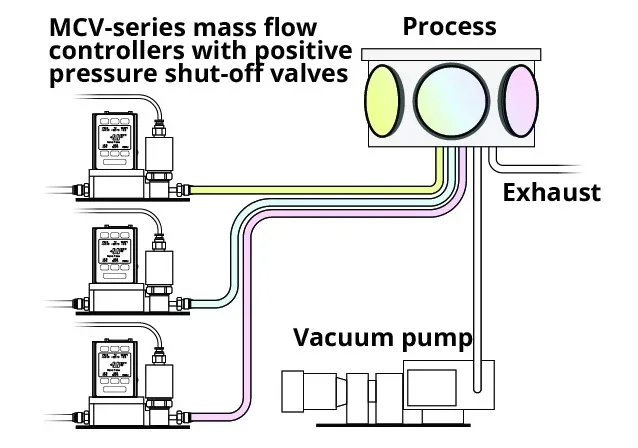

The MCE-Series and MCV-Series mass flow controllers are built to replace legacy devices. To further ensure easy integration, instruments are available with a variety of digital and analog communication protocols including EtherCAT.

Products

Products

CODA Coriolis mass flow controllers precisely control DI water or high pressure gases.

Hydrogen mass flow meters with integrated totalizers make monitoring easy, up to 10,000 SLPM.

Hydrogen mass flow controllers mimic fuel cell behaviors at full scale flow rates up to 10,000 SLPM with quick response and high accuracy.

Dual-valve pressure controllers reach setpoints in milliseconds and maintain control without continuous bleeding.

CODA Coriolis mass flow controllers precisely control

CODA Coriolis mass flow controllers precisely control  Hydrogen mass flow controllers

Hydrogen mass flow controllers Dual-valve controllers reach setpoints in milliseconds and maintain control

Dual-valve controllers reach setpoints in milliseconds and maintain control