Aerospace and Defense

Alicat flow and pressure instruments accurately characterize flow and leak test valves and thrusters. Devices are trusted in countless manufacturing processes including environment control, handling of coolants, and welding stations.Manufacture and test mission-critical components and systems

Devices are preconfigured with your choice of STP/NTP conditions and engineering units, and are easily adjustable in the field without requiring recalibration. AS5202 porting and easy-to-use electronics ensure simple integration with standard NASA and other test bench equipment. The responsive, data-rich display on any Alicat enables you to easily monitor the health of your process. Other common Alicat flow and pressure instruments applications include:- Satellite altitude control testing

- Gas mixing to emulate exotic atmospheres

- Buoyancy testing requiring accurate totalizing and dosing

- Breathing simulation

Applications

Control flow instruments directly using process pressures

Use the PC-EXTSEN pressure controller to send a voltage signal directly from a 20,000 PSI transducer to an Alicat piloting a dome-loaded pressure regulator. Controlling using actual process pressure improves response times and minimizes fluctuations. Pressure control for aerodynamic testing

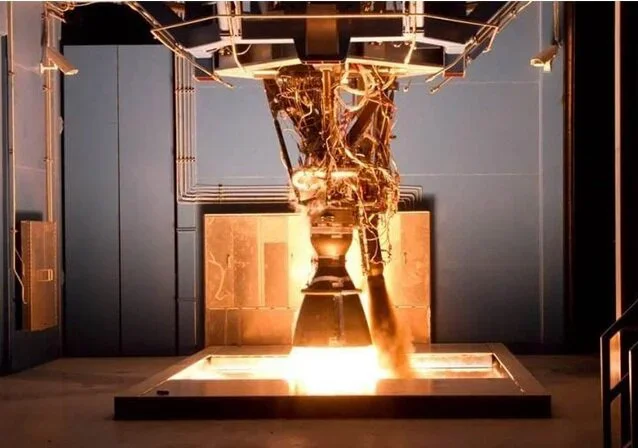

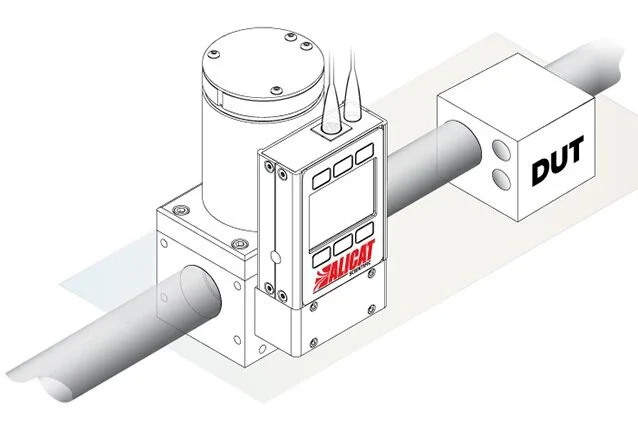

Leak testing and characterizing mission-critical systems

Direct pneumatic pressure controllers at 3,000 PSI are ideal for leak testing and characterizing thrust-producing flow components like throttle plates.

Argon or nitrogen can be used as surrogate gases for testing, with flow and pressure controllers easily able to switch between flowing different gases.

Products

CODA Coriolis mass flow controllers precisely control DI water or high pressure gases.

Hydrogen mass flow meters with integrated totalizers make monitoring easy, up to 10,000 SLPM.

Hydrogen mass flow controllers mimic fuel cell behaviors at full scale flow rates up to 10,000 SLPM with quick response and high accuracy.

Dual-valve pressure controllers reach setpoints in milliseconds and maintain control without continuous bleeding.