Aerobic and anaerobic wastewater treatment

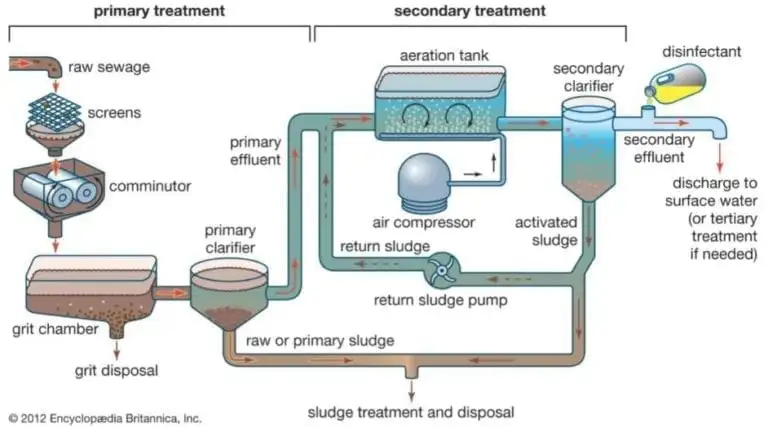

Conventional wastewater treatment in the US consists of three distinct steps: primary, secondary, and tertiary.

- Primary treatment involves the removal of solids by sedimentation or flotation.

- Secondary treatment involves the removal of organic matter through microbial decomposition.

- Finally, tertiary treatment is any additional treatment that the wastewater might have to undergo if it is reused, recycled, or discharged to the environment.

After the primary effluent leaves primary treatment, it is introduced into a specially designed bioreactor where the organic matter is utilized by microorganisms such as bacteria, algae, or fungi for either aerobic or anaerobic wastewater treatment.

The selection of the secondary treatment may depend on several factors like nature of wastewater, chemical and biological oxygen demand (COD & BOD), energy demands, treatment time, investment, operational and maintenance costs, sludge production, space requirements, desired effluent quality, and microbial concentration. An optimum configuration would, more often than not, utilize a combination of these two technologies.

Aerobic treatment is typically applied to efficiently treat low strength wastewater (COD <1000 mg/L) when the treatment requires the presence of oxygen. Whereas, anaerobic treatment is typically applied to treat wastewater with higher organic loading (COD >4000 mg/L).

Mass flow in aerobic/anaerobic processes

Aerobic treatment utilizes oxygen and bacterial biomass to assimilate organic matter and other pollutants like nitrogen and phosphorus into carbon dioxide, water, and other biomass. On the other hand, anaerobic treatment, as the name suggests, breaks down organic impurities in the absence of oxygen to produce methane, carbon dioxide, and other biomass. Mass flow controllers and meters are critical to achieve fast, accurate, and stable flows of air and oxygen in an aerobic process. Mass flow meters can be used to monitor fast, accurate and stable flows of methane and carbon dioxide in an anaerobic process.

Advantages and disadvantages of aerobic and anaerobic processes

Aerobic treatment has some distinct advantages over the anaerobic treatment process. These include reduced odor (due to non-production of hydrogen sulfide or methane) and better nutrient removal efficacy (facilitating direct discharge into surface waters or disinfection). However, aerobic treatment does have several disadvantages. Oxygenation is an energy-intensive process severely increasing the overall energy consumption, utility and maintenance costs of this process. Solid wastes that the microbes are unable to digest often settle out as bio-solids. These bio-solids require appropriate disposal adding to the utility and maintenance costs.

Anaerobic wastewater treatment processes, on the other hand, have a number of advantages over aerobic treatment processes. The biogas produced during an anaerobic treatment process can be used as a source of renewable energy (natural gas/methane). This also produces very low sludge that is de-waterable and fully stabilized for disposal. This makes it less expensive, simple, and flexible when compared to most aerobic treatment processes.

Since both of these methods have their own advantages and disadvantages, often a combination of anaerobic and aerobic treatment processes are employed to achieve efficient treatment of wastewater. The wastewater going into the aerobic reactor will often undergo pre-treatment in an anaerobic reactor to fulfill wastewater standard discharge requirements in an energy efficient and cost-effective manner.

Key differences between aerobic and anaerobic processes

* CH 4 generated can be used to generate energy

Conclusion

In the past few decades, bioreactor usage in the course of wastewater treatment has moved from an exotic, new technology to a standard process. A key strategy for optimization of these systems is to measure input and/or output gasses in order to understand and control the process efficiently. The precise usage of aerobic vs. anaerobic wastewater treatment processes depends on factors unique to each facility, and metering of mass flow is essential to understanding how best to utilize available tools to provide an optimal treatment regimen.