Using FB-CVD for TRISO nuclear fuel particle manufacturing

Six types of Generation IV nuclear reactors represent the next stage of improved safety, sustainability, efficiency, and cost of design for providing nuclear energy. Among them are:

- Supercritical water-cooled reactors (SCWR)

- Lead fast reactors (LFR)

- Sodium fast reactors (SFR)

- Molten salt reactors (MSR)

- High temperature gas-cooled fast reactors (HTGR)

- Very-high-temperature reactors (VHTR)

This article focuses primarily on high temperature gas-cooled reactor types to describe the tristructural-isotropic (TRISO) nuclear fuel particle manufacturing process. TRISO nuclear fuel particles are the main power source in HTGR reactors, but can also be used in fluoride-salt-cooled high temperature reactors (FHRs) and light water reactors (LWR).

TRISO nuclear fuel particles

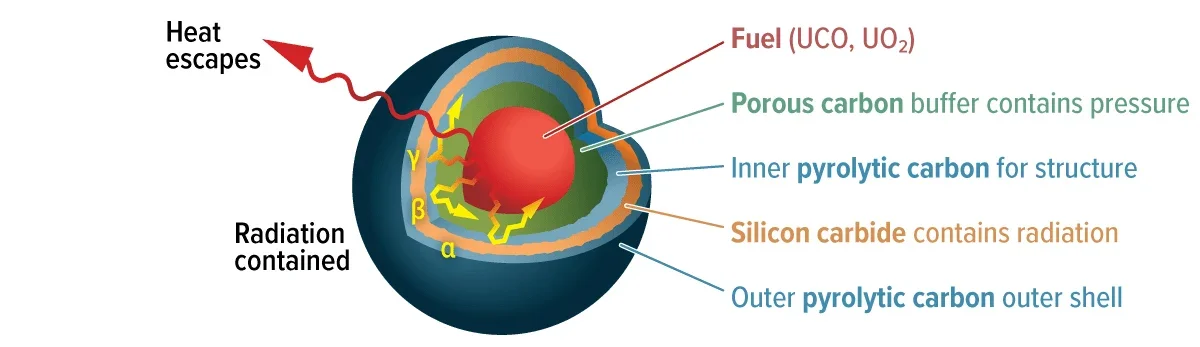

TRISO nuclear fuel particles consist of various UOX chemicals, such as UO2, which have been coated with four layers of three isotropic materials deposited as a protective kernel. These four layers are:

- Buffer PyC layer

- Inner PyC layer

- SiC layer

- Outer PyC layer

TRISO nuclear fuel particles avoid breaking from process stresses such as differential thermal expansion and fission gas pressures up to temperatures of 1600°C. Since these reactors operate around 750°C, the radioactive fuel elements are insulated during the worst of meltdown scenarios in a properly designed reactor. In other words, all the radioactive fission products produced during the reaction process are confined within the fuel so there is no release of radioactivity from the fuel particles to the outside world, even way outside typical operating conditions (up to 1600°C).

FB-CVD TRISO manufacturing

The main process for the deposition of these isotropic material layers to form TRISO nuclear fuel particles is a technique called fluidized bed-chemical vapor deposition (FB-CVD). In the FB-CVD process, the nuclear fuel UOX kernels are fluidized by a fluidization gas and coated by a reactive gas in a heated spouted bed coating furnace.

- The buffer PyC layer is prepared using acetylene as the reactant gas and argon as the fluidization gas at a chamber temperature of about 1260°C.

- The inner and outer PyC layers use propylene as the reactant gas and argon as the fluidization gas at chamber temperatures of 1280-1300°C.

- Conversely, the SiC coating layer is prepared using MTS vapor as the reactive gas pyrolyzed with hydrogen as the fluidization gas at chamber temperatures around 1600°C.

FB-CVD TRISO flow control

The various gas flow rates and reaction times for creating each of the four layers varies based on the size of the nuclear fuel kernels, increasing when using larger sized particles. Flow rates and reaction times also change based on which gas is currently used, the size of the system, and pressure and temperature conditions. Therefore, accurate and repeatable gas flow control is critical to maximize the process efficiency of these systems, ensuring that TRISO nuclear fuels satisfy safety and process tolerances.

Alicat’s MC-Series of gas mass flow controllers allow for accurate and repeatable gas flow control in FB-CVD systems.

- Accuracy up to 0.8% of reading and ±0.2% of full scale

- Repeatability (2σ) up to just ±0.2% of reading + 0.02% of full scale

- Control within .01-100% of full scale from just a .5 SCCM full scale all the way up to a 5000 SLPM full scale

Whereas the hydrogen, acetylene, and argon gases are suitable for MC-Series gas mass flow controllers, propylene is better suited to an MCS-Series which offers greater corrosion-resistance. These anti-corrosive gas flow controllers use stainless steel wetted materials for improved compatibility with corrosive gases.

- Accuracy up to ±0.8% of reading and ±0.2% of full scale

- Repeatability up to ±0.2% of full scale

- Control flow rates between 0.5 SCCM full scale through 5000 SLPM full scale

- 1-100% full scale control range