Clamp-on flow meters and Alicat portable flow meters

A key benefit of portable flow meters is their ability to measure flow without needing to be built into your process. Here we analyze two portable flow meter technologies: the commonly used ultrasonic clamp-on flow meter and the Alicat portable differential pressure-based mass flow meter. We will discuss their operating principles, features, and common applications to determine when it may be better to use one or the other.

Operating principles

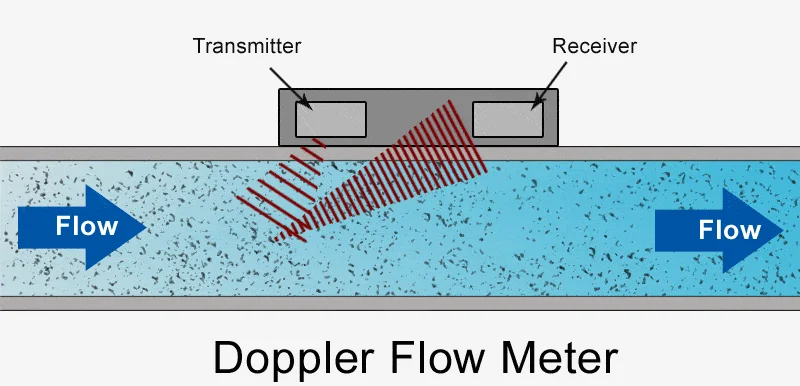

Doppler flow ultrasonic clamp-on flow meter operating principle

Doppler clamp-on flow meters utilize the Doppler Effect to measure fluid flow. These work by transmitting ultrasonic waves into the fluid, which are then reflected back to the sensor by particles or bubbles in the flowing fluid. The frequency change between the transmitted and received waves is used to calculate the flow velocity.

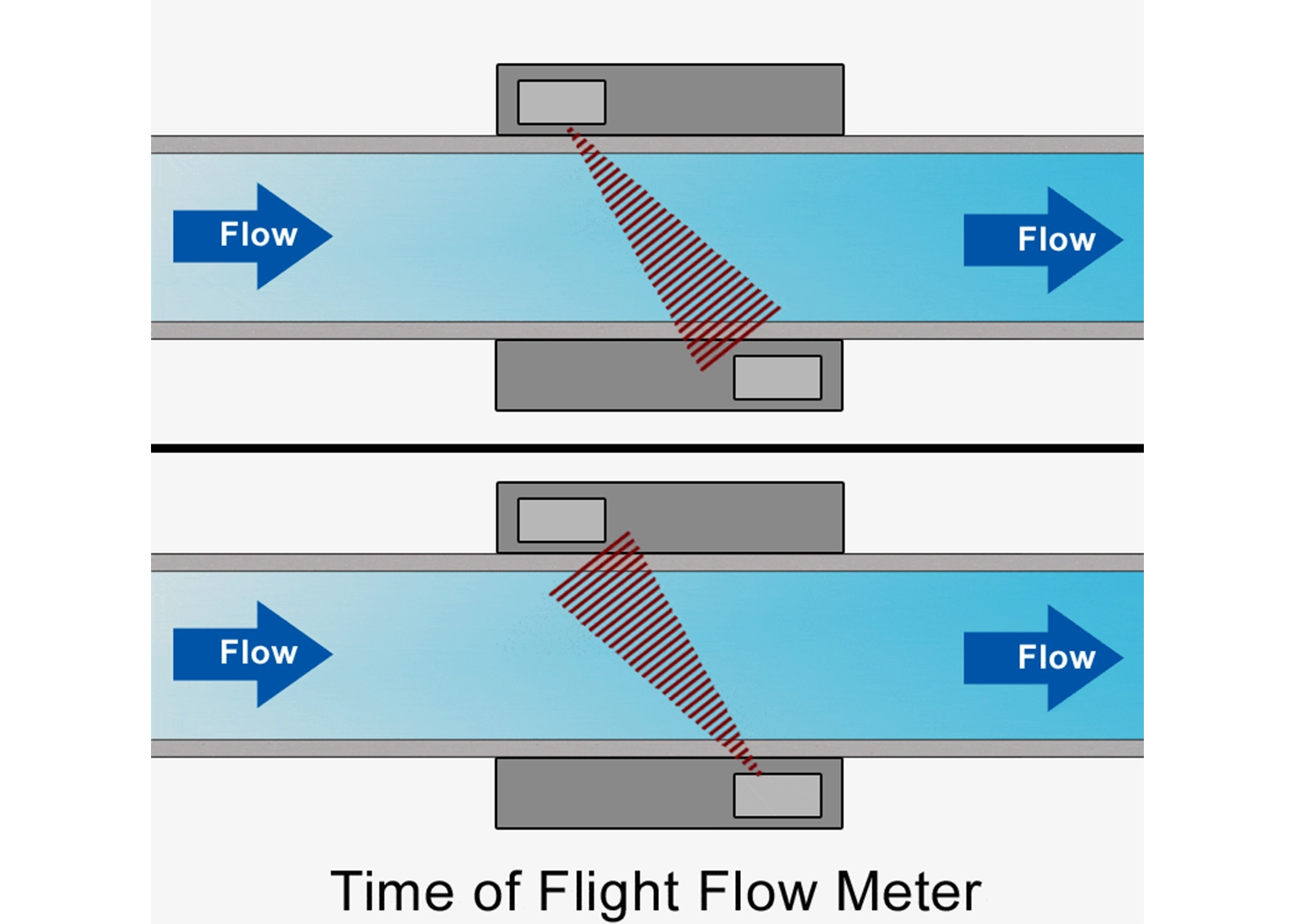

Transit time ultrasonic clamp-on flow meter operating principle

Transit ultrasonic clamp-on flow meters measure flow using ultrasonic wave travel time. One wave is sent from an upstream to downstream transducer, and another wave is sent from the downstream to upstream transducer. The difference between the two travel times is used to calculate flow velocity.

Figure 1. Ultrasonic Doppler flow meter principle of operation

Figure 2. Ultrasonic time-of-flight flow meter principle of operation

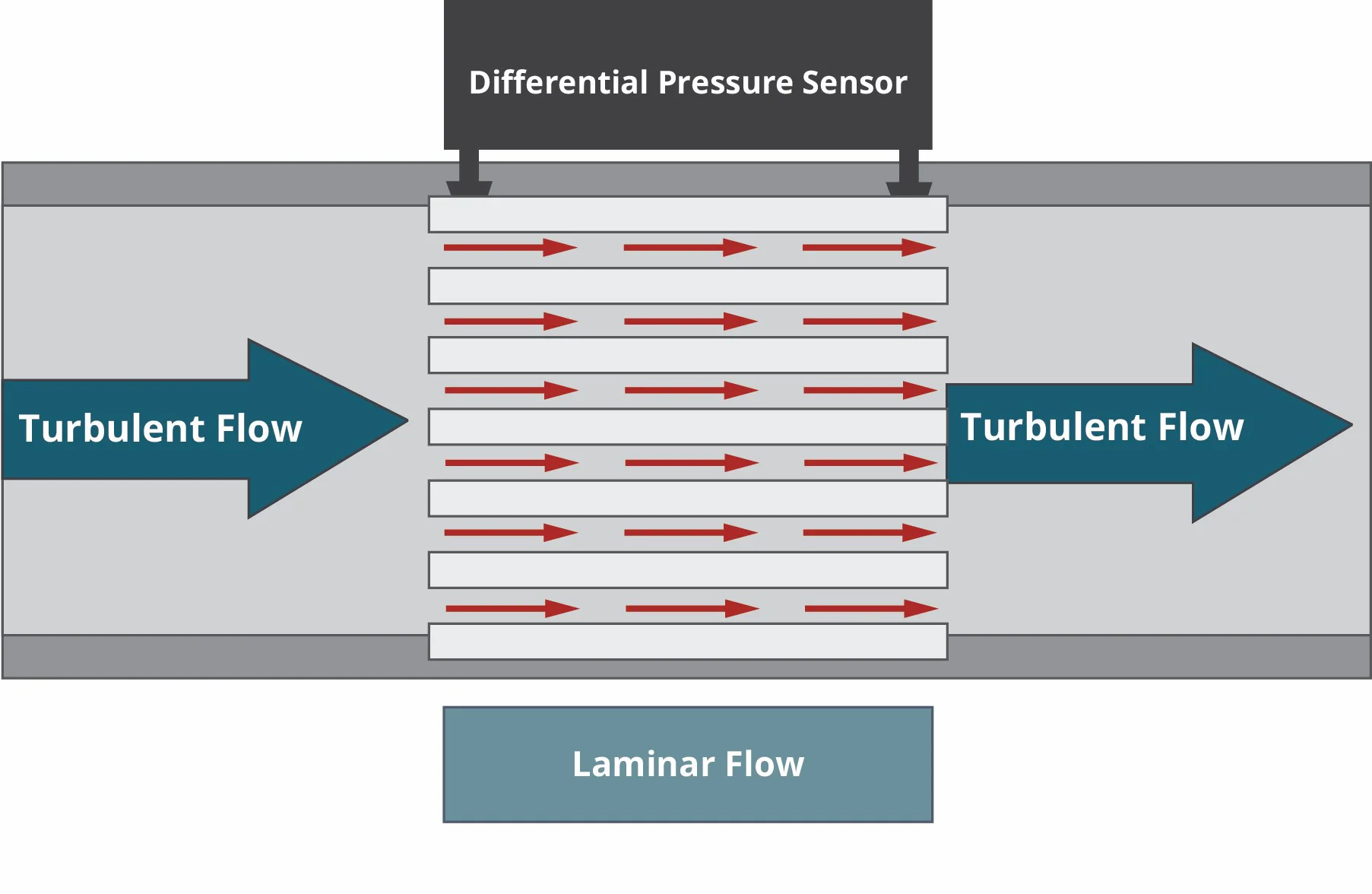

Alicat portable flow meter operating principle

Alicat portable flow meters are a battery powered version of the core technology found in our standard mass flow meters. They use the pressure drop created within a laminar flow element (LFE) to measure mass flow. First, the LFE converts turbulent flow into laminar flow, and a differential pressure (DP) sensor measures pressure drop across the element. The Poiseuille equation is then used to calculate volumetric flow, which is converted into a mass flow rate using temperature and absolute pressure measurements in conjunction with known gas properties.

Features of clamp-on and Alicat portable flow meters

In-line or clamp-on?

Clamp-on flow meters can be attached to the outside of pipe fixtures, making them excellent for non-invasive flow measurement. Alicat portable flow meters take measurements in-line, so the system flow must be paused or diverted while the unit is plumbed into the system.

Accuracy?

Clamp-on flow meters are very good at measuring fluid velocities. In order to convert those velocity measurements into useful engineering units of measure, both the inside diameter of the pipe and the fluid density must be known. The accuracy of clamp-on flow meters may therefore be influenced by changes in fluid flow dynamics caused by bends and junctions in piping, and also by variations in pipe diameter arising from both corrosion and debris build-up. Additionally, clamp-on meters are particularly susceptible to external vibrations as they are attached to the outside of piping. Clamp-on flow meters tend to measure with an accuracy of ±%2 to ±5% of reading.

Alicat portable flow meters are equipped with absolute pressure and temperatures sensors, so they can accurately calculate volumetric and mass flow rates even with changing fluid densities. Most units have an accuracy of ±0.6% of reading or ±0.1% of full scale (whichever is greater).

Ultrasonic clamp-on flow meter

Pressure drop

Clamp-on flow meters produce zero pressure drop and work well in processes where pressure drop may be disruptive.

The standard Alicat portable flow meter can maintain a pressure drop as low as 1.0 PSID at full scale. For low-pressure applications, the low pressure drop portable flow meter can be used to maintain a pressure drop as low as 0.07 PSID at full scale.

Alicat MB-Series mass flow meter in the field

Single-phase or multi-phase?

Depending on the technology, clamp-on flow meters can be used for clean or dirty flow. Transit time clamp-on flow meters are used to flow clean, single-phase fluids without particulates or bubbles. Doppler clamp-on flow meters, on the other hand, are used for multi-phase fluids containing bubbles or particulates – which is why they are often used for wastewater flows. The caveat is that the particulate must flow at the same rate as the fluid, otherwise only the slower flow of the particle will be measured.

Like most mass flow technologies, Alicat portable flow meters require flow of a single-phase fluid to provide accurate mass flow readings. The fluid also needs to be clean, as bubbles and particulates can get caught in the LFE and disrupt flow and readings.

Fluid composition?

Alicat portable flow meters utilize gas properties to calculate accurate mass flow rates. These portable flow meters come pre-loaded with 98+ gases and a COMPOSER™ function for defining known gas mixes, and can be adjusted to flow different gases without the need for recalibration. There is also an anti-corrosive meter available for processes with aggressive fluids that are incompatible with the standard meter.

If you are flowing a gas that is not pre-loaded, cannot be configured with the COMPOSER™ function, or that is incompatible with the wetted materials of the flow meter, a clamp-on portable flow meter may be a better option as it measures flow rate independently of fluid composition and without coming into contact with the flow.

Moisture?

Although Alicat portable flow meters are resistant to low levels of moisture, sudden liquid bursts in a gas line can damage them. In processes where this may be a risk, a clamp-on flow meter may be a safer option.

Common applications for clamp-on and Alicat portable flow meters

Each of these technologies is best suited for distinct applications that take advantage of their unique strengths and weaknesses. Clamp-on portable flow meters are extremely convenient since they don’t have to be dropped in-line. Common clamp-on flow meters applications include wastewater management, natural gas processing, and compressed air.

On the other hand, Alicat portable flow meters are an excellent option for high-accuracy process validation, verification, and calibration in the field. A few processes they are used in include natural gas monitoring and gas chromatography.