Bioreactor and Fermentation

Repeatable and scalable flow control is crucial to achieving high titers from upstream bioprocesses. Designing robust control systems with closed-loop control on parameters like pH and dissolved oxygen leads to predictable, scalable, bioreactor and fermenter yields.

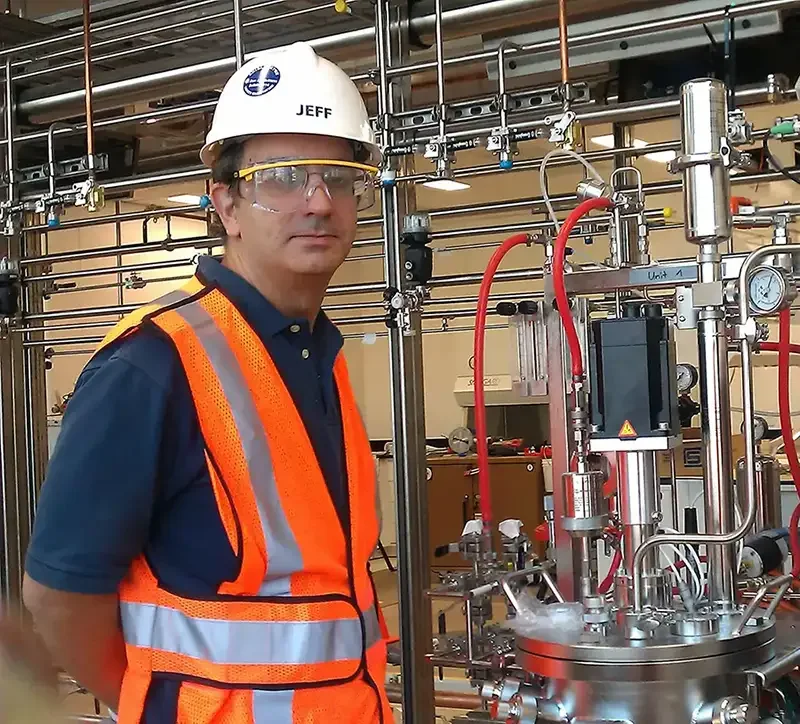

Automate and scale bioreactor and fermentation control systems

Flow controllers easily integrate into pre-existing data systems, ensuring data integrity and facilitating the progression through process development stages.

Alicat instruments minimize downtime and device footprint, while maintaining accuracy and functionality.

- Preconfigured for bioprocessing – and fully customizable. Time-tested hardware and software, with USP Class VI elastomers and 316L stainless steel flow bodies, combine to form the Bio-Series – which can be further configured to slot perfectly into any system.

- Built-in redundancies. The standup interface gives multi-parameter information in a single glance, including valve drive usage for preventative maintenance.

Product guides

Applications

Minimizing flow lines and reducing spares inventory simplifies operation and maintenance

A wide 10,000:1 turndown means a single Alicat can be swapped into any point in this system with no need for recalibration.

One global biologics manufacturer used Alicat to simplify the flow lines at its commercial production facility, decreasing failure points and minimizing the need for spares.

Flow systems for every phase of biologics development

Use our standard devices, or work with our engineering team on a custom setup designed to meet exact process requirements.

For scientists, flexibility to experiment with cell lines and seed trains

For automation engineers, scalability to integrate control systems early

For system designers, configuration and customization for validated systems

Back pressure control and drop-in compatibility for scale out and scale down

Unlocking new possibilities in bioreactor design

Tools to use for pharmaceutical scale-up

Headspace monitoring for real-time control of culture growth

While more resource intensive than simply measuring dissolved oxygen and pH, it maximizes yield and improves scalability.

The benefits of hybrid facilities in biologics systems

Products

CODA Coriolis mass flow controllers precisely measure and control liquids, with options for batching.

Dual-valve pressure controllers reach setpoints in milliseconds and maintain control without continuous bleeding.

Further Reading

- Shakers, rockers, and stirred tank bioreactors – advantages of each

- Four methods to control pH in bioreactors

- Inflating single-use bioreactor bags using dual-valve pressure controllers

- Single-Use Bioreactors vs Stainless Steel on Environment

- Five tools to optimize bioreactor production

- Compact Gassing Modules Simplify Benchtop Bioreactors

- Control systems for benchtop bioreactors

- Addressing scaling challenges of bioreactor sparging using mass flow control

- Reducing Bioreactor Footprint

- Switching to single-use bioreactors

- Alicat mass flow controllers resist back pressure contamination

- Advantages of single-use plastic bioreactors in small-scale bioprocessing

- ILS Automation integrates mass flow control with industrial communication protocols into bioreactors

- Mass flow controllers for bioprocessing applications

- Accurate and simplified pressure decay leak testing for single-use bioprocessing

- High flow control for gasification

- Mass flow control for microbial fuel cells and microbial electrolysis cells for hydrogen production

- Lowering cost and increasing speed of biologics production